R&D Team

- Nearly 30 MIM technicians and engineers

- Professional teams Engaged in new product development, process, tooling, automation and other professional work

- Assistant teams, such as AM, PM, QC, and etc.

- Our consultant employ several top experts in the MIM industry

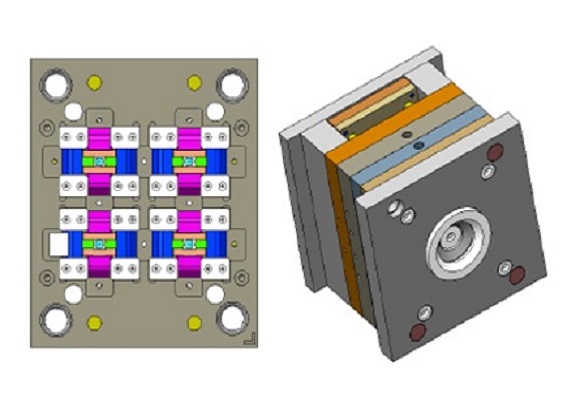

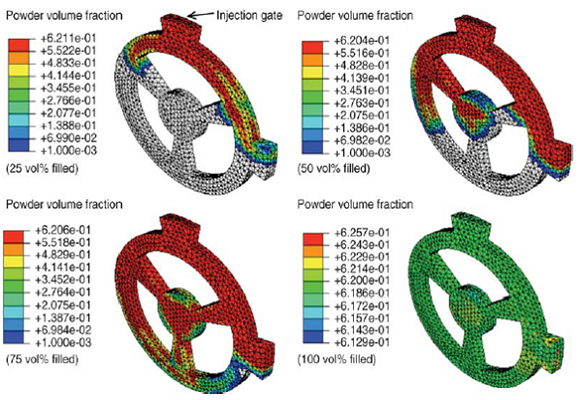

Tooling Design

JUN have highly trained design and engineering team that can turn your ideas into reality. Our strictly managed engineers are familiar with MIM production, injection molds, fixture and measure instruments. We utilize 3D software, such as Pro Engineer and Unigraphics NX. We offer one stop design services, which includes industry design, FEA, 3D process analysis, mold flow analysis, etc.

Equipment of Tooling Manufacturing

A core technologies and competences of JUN is our ability to design and manufacture our tooling in house. We believe this is a critical asset to deliver high quality, high precision MIM products in an efficient and low cost. We have sufficient capacity to handle design modifications and meet customers’ urgent requirements. We are constantly investing in the latest machines and technology to improve our speed and precision.

Production Equipments

Feedstock Mixing/Pelletizing

Material Design

Professional Material Engineer and the most famous consultant.

Precision and high end instruments and technologies. (ICP, SEM-EDX, X-ray & Metallographic analysis technology )

Feedstock Design

Feedstock Mixer/Pelletizing Unit for Hard alloy 2 units (5L Volume )

Feedstock Mixer/Pelletizing Unit for Stainless Steel and Fe-based alloy 2 units (5L Volume )

Feedstock pelletizing 8 devices

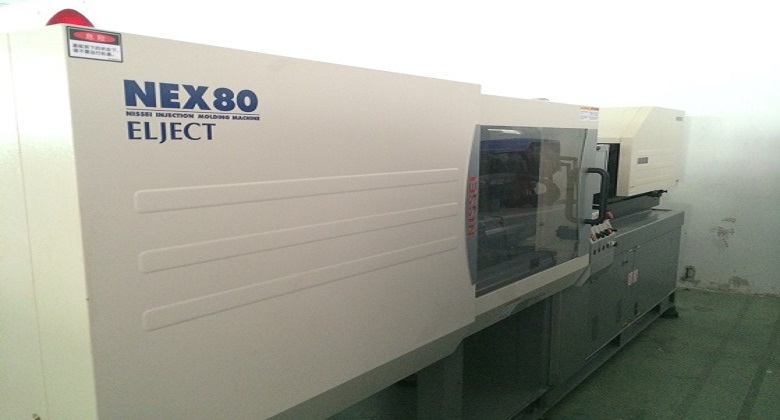

Production Equipment– Injection

Injection

Full Electric driving Injection Machine 40 devices(110 Tons, Maximum Speed 300mm/S)

The injection production capacity can be expanded by 20 units per week, which can increase efficiently. The injection site of our company is abundant and the expansion capacity is not worrying.

Production Equipment– Comprehensive De-binding Technology

Solvent De-binding for Wax based feedstock

Hard alloy/oxidizing alloy de-binding

Solvent de-binding 13 devices (960L, solvent volume)

Catalytic De-binding for POM based feedstock

Special for lab 1 device (120L,volume)

Nitric acid de-binding for mass production 2 devices (300L, volume)

Thermal De-binding

Thermal de-binding by vacuum 1device (300L, highest temperature 1000℃)

Continuous thermal de-binding with single plate Hydrogen Atmosphere 22devices (14M, highest temperature 1000℃)

Production Equipment–Sintering

Batch Sintering

Batch vacuum sintering furnace-Metal Thermal Field 1 device (240L, highest temperature 1500℃)

Batch vacuum sintering furnace- Graphite Thermal Field 4 device (240L, highest temperature 1550℃)

Expected additions 18 devices (2019~2020)

Progressive Sintering

Tunnel Furnace with Single Push Plate and Hydrogen Atmosphere 20 devices (6.3meters, highest temperature 1500℃)

Equipment–Finishing and Post Process

JUN have various kinds of finishing operations equipment and technical:

CNC machining operations to achieve tolerances

Restriking to improve precision

Heat treatment to improve physical properties

Magnetic grinding to improve surface performance

Laser marking or etching

Post treatment

Vacuum heat treatment furnace 3 devices (300L, highest temperature 1200℃)

* Remarks:

The vacuum heat treatment furnace of our company can provide sintering parts heat treatment process, including vacuum annealing, tempering and product structure (austenite), eliminating the internal stress of products, and make the size and mechanical properties of products more stable.

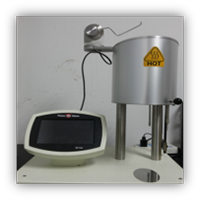

Quality Control Equipment — Inspection and R&D

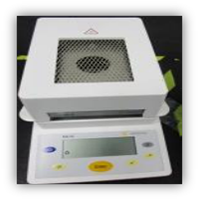

Physical property

MFI, Moisture, Density and Hardness.

Dimension and appearance

Caliper and Height gage

Physical gauge and 3D-OMM

Nondestructive Examination

Microscope, SEM, X-ray, and EDX etc.